Successful Innovations & Collaborations

Added Value by Integrating Multiphysics Simulation

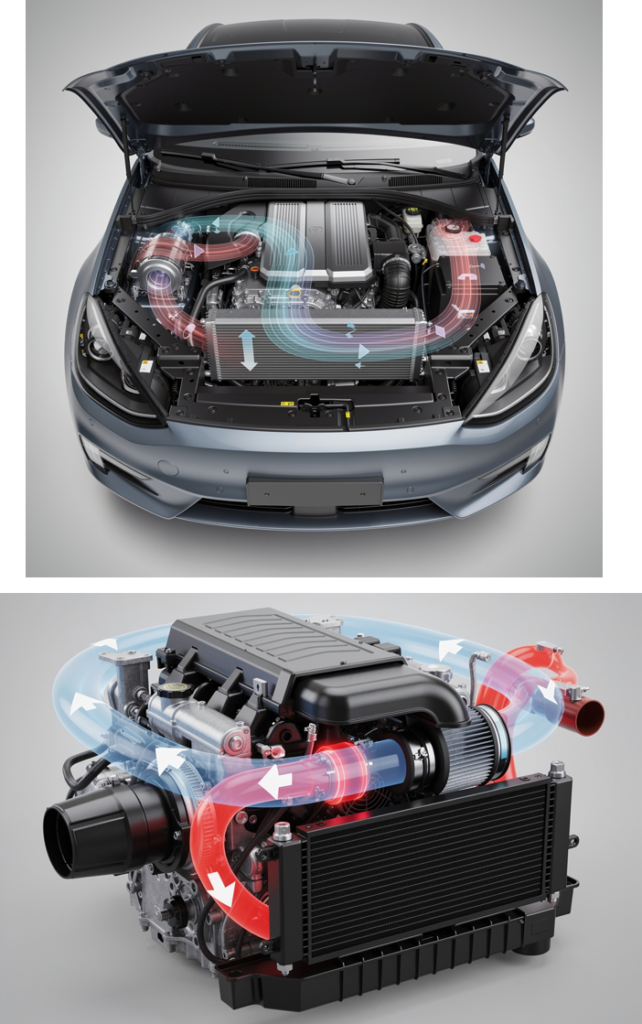

Multiphysics Simulation: Under-the-Hood Engine Parts

Selection and characterization of materials according to OEM specifications. Based on manufacturer requirements: fluid temperature, mass flow rate, and external environment.

Optimization of design and material selection through CFD simulation (fluid and thermal). Precise evaluation of the real temperature on the part and the temperature gradient.

Temperature: a key criterion for material selection. Beyond certain thermal thresholds, the use of reinforced materials is mandatory. Re-evaluation of initial choices.

Thermal and fluidic issue resolution: Analysis of hot spots, risk areas (leaks), and pressure drops. Evaluation of fluid temperatures at inlet and outlet.

Thermal and mechanical behavior analysis for all under-the-hood components in internal combustion engine vehicles. Adaptable method for all applications.

Alignment of input specifications with real-world conditions. Optimization of test protocols to reflect usage scenarios and real-life conditions.

Weight reduction and functional integration: optimization of thickness and minimizing the number of parts. Integration of constraints (space, cost, thermal performance).

Evaluation of trends and risks based on vehicle use cases. Extreme scenarios (cold, heat, mountain, highway) or reusing the same part for another vehicle.

Use of multiphysics simulation (CFD + DOE) to ensure success. Coupling of mechanical, thermal, and fluid analyses. Validation of designs through DOE (Design of Experiments).

Subscribe to our newsletter

Sign up to receive the latest updates, news, and tips.