At MultiPhysX Consulting, we combine design expertise, digital engineering, and advanced materials (thermoplastics, composites, metals) with innovative methods to maximize the performance of your products.

Our strength ? A multidisciplinary approach, based on the integration of key skills:

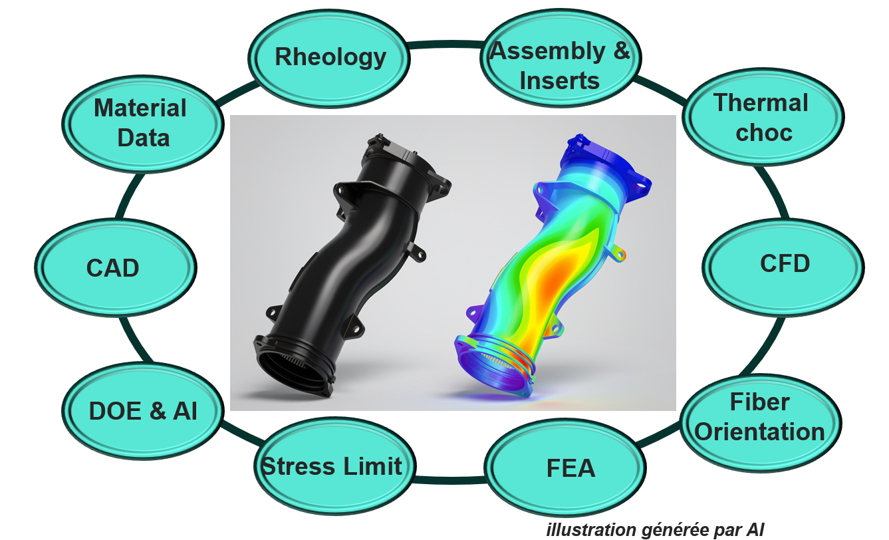

Computer-Aided Design (CAD)

Model your parts with precision, analyze your design, and share best practices to ensure parts of superior quality.

Material Data

Understand and anticipate material behavior at every level: mechanical and thermal stresses, manufacturing process impact, assembly, glass fiber effects, weld lines, and more.

Allowable Design Stress

Avoid purely theoretical simulation results by comparing them to the real-world material limits under actual usage conditions. A scientific method to assess the risk of failure between simulation and the selected material.

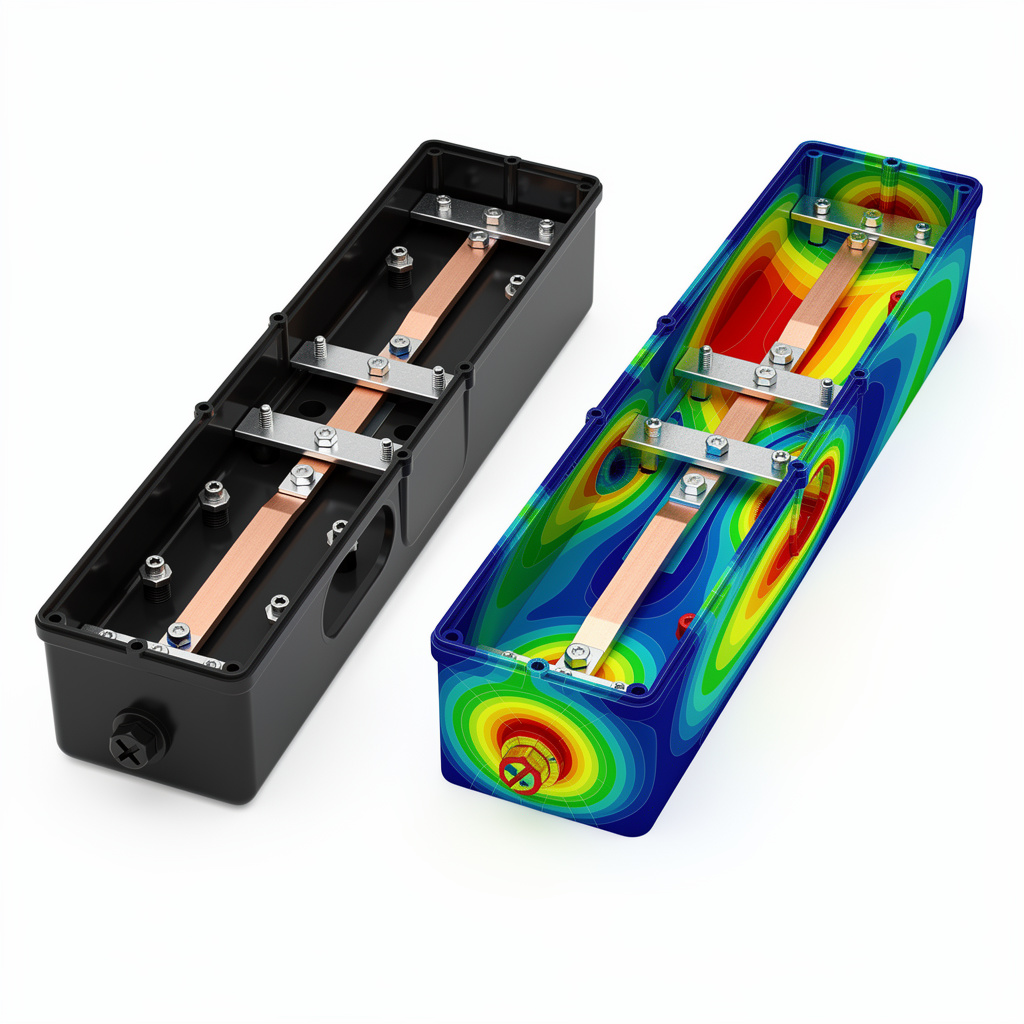

Assembly et Inserts

(Metal and Composite)

The choice of assembly should be guided by the selected materials, as well as technical and economic requirements. The impact of surrounding components must be integrated from the design phase to ensure the reliability and quality of the final product.

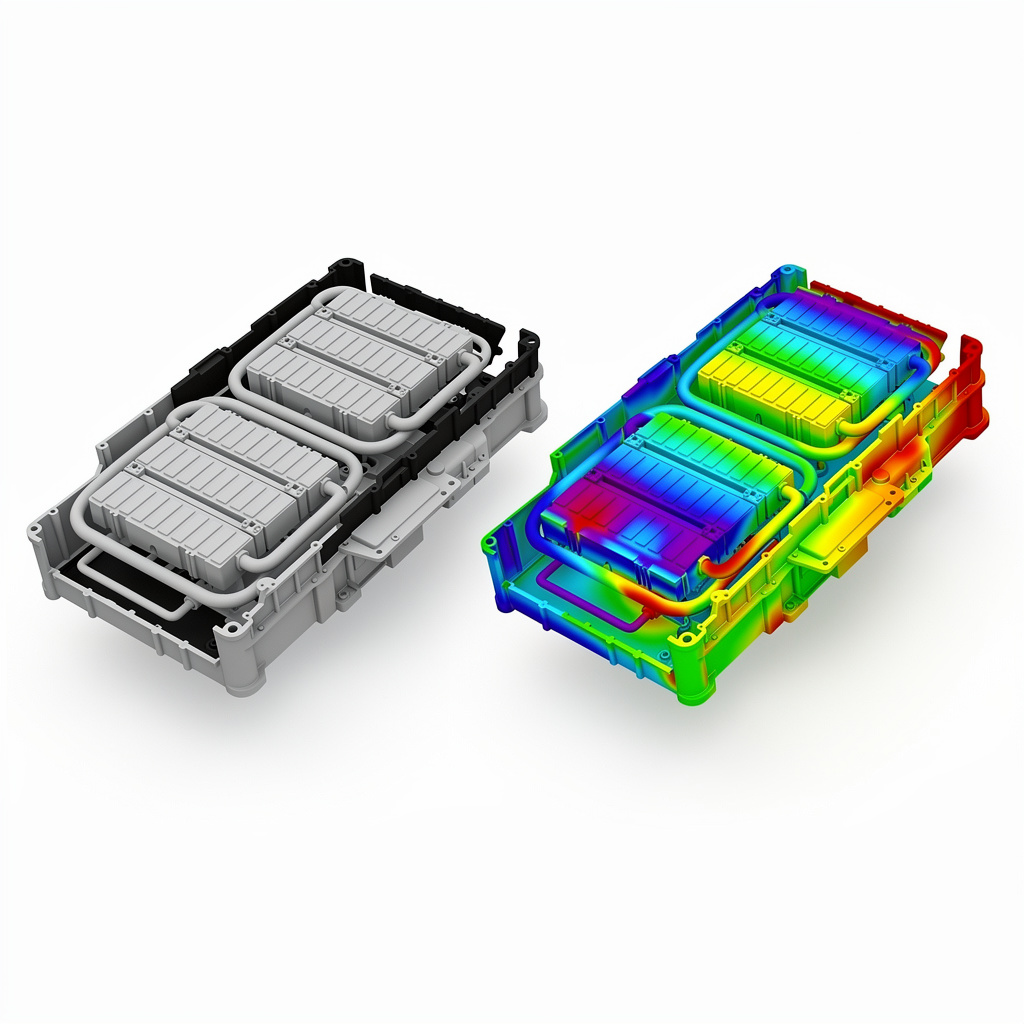

Thermal Shock analysis

(FEA & CFD)

Ensure the effectiveness of your components, even under extreme conditions. We offer design and process solutions to minimize functional failures.

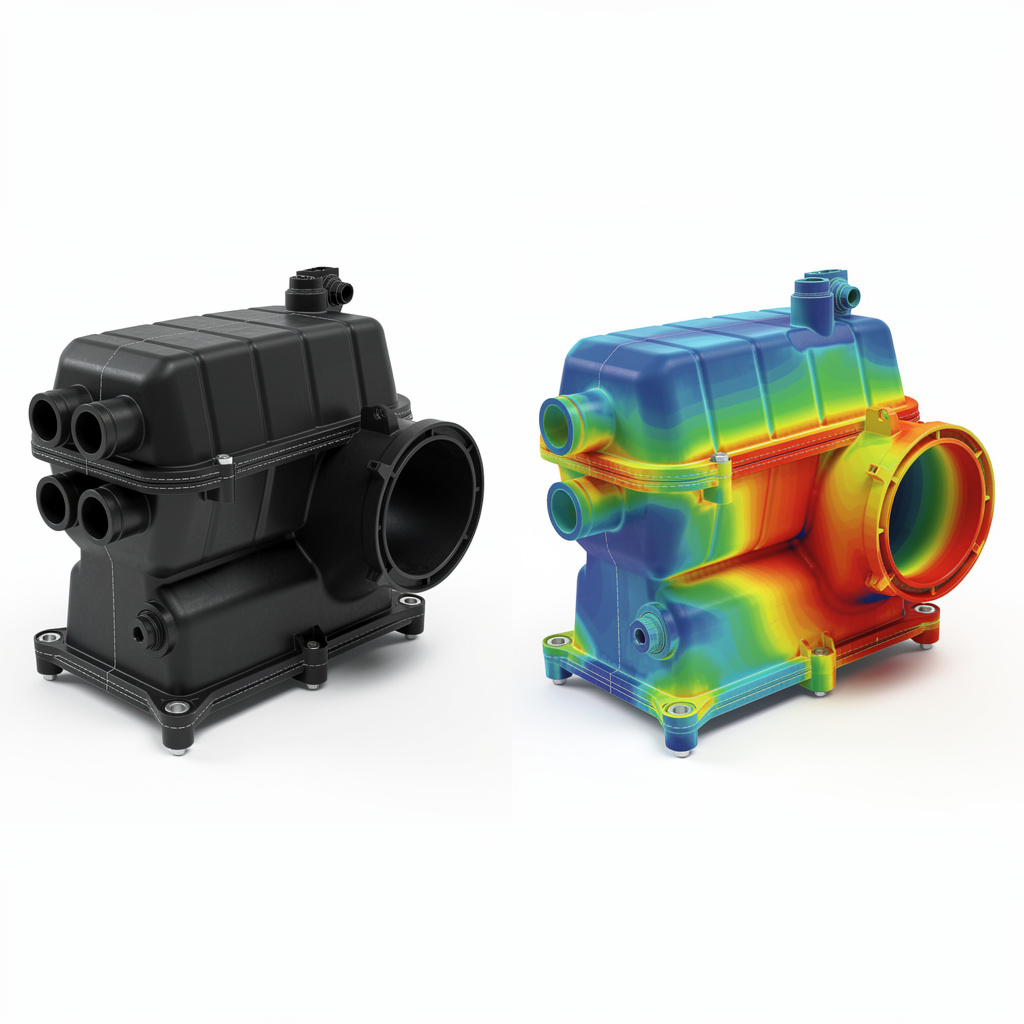

Finite Element Analysis

(FEA)

Assess mechanical stresses and part strength. Identify high-risk areas and propose simple, reliable solutions to ensure long-lasting performance.

Fiber orientation

The use of reinforced materials—whether glass fibers, carbon fibers, or mineral fillers—should not be taken lightly, even though they significantly enhance mechanical performance. Their impact must be considered from the outset of the project, as it affects material properties, rheology, assembly, interaction with inserts, thermal shock resistance, and both CFD and mechanical calculations.

Computational Fluid Dynamics

This is a powerful tool that translates the requirements of a specification sheet into realistic data about the parts. It provides a detailed analysis of temperatures, thermal gradients, hot spots, and turbulence, enabling the optimization of material selection based on the actual temperatures experienced by the plastic component.

Rheology

It is essential to integrate process-related constraints from the design phase. Inappropriate settings or conditions can indeed compromise even the best designs, leading to issues such as material degradation during injection, poor injection gate location or weld lines, incorrect glass fiber orientation, warping defects, and many other risks that must be anticipated.

Subscribe to our newsletter

Sign up to receive the latest updates, news, and tips.